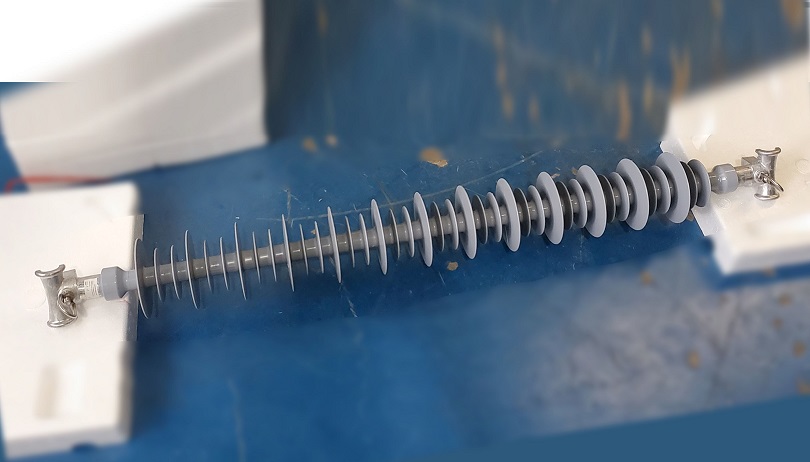

The Inter-Phase Spacers is a kind of composite insulator, which consist of housing (sheds and sheath) that made by injection molded over an ECR fiberglass rod and end-fittings. The advantages of the composite Inter-Phase spacers are lightweight and flexible, Inter-Phase Spacers are designed to meet the torsional, bending and compression loads of the application.

The performance benefits of InterPhase Spacer Insulators are listed below:

- Improves Reliability (minimizes interruptions and outages due to conductor contact, flashovers or plant

- damage in all types of environments

- Safety (light weight for handling and installation)

- Service Life (consistent performance over its service life)

- Life Cycle Cost (savings over porcelain insulators)

Housing (sheath and sheds)

Sheath and sheds of composite long rod polymer Insulators are made of HTV silicone-rubber (VMQ - Vinyl-Methyl-Polysiloxane, with filler additives) free of EPDM or other natural origin rubbers.Silicone-rubber is HTV solid silicone type (High Temperature Vulcanized – solid silicone rubber).This type of silicone rubber is solid and vulcanizes at a high temperature (near 200ºC).

Core

The ECR fiberglass rod, which produced from epoxy resin and glass fiber, has ability of high electrical integrity & high resistance to acid corrosion. Epoxy resin resistant to hydrolisys reinforced with glass fiber resistant to corrosion in order to transmit the mechanical stresses produced by conductors to the support and provides the necessary electrical insulation.The core is the component to bear mechanical load and has minimum tension strength at 1000Mpa.