Overview

The composite station post insulators are widely applied to disconnector,devices in electric transformer substations, convertor stations and tubular bus-bar and other primary equipment. With so many special advantages, composite station post insulator is increasing its market shares. According to company standard Q/GDW-383 SMART CONVERTOR TECHNOLOGY GUIDE, which is stated by State Grid Corporation of China, “primary equipment should be with high reliability, apply composition material as outer insulation, and suitable for the working environment.

According to customers requirements, post insulator can be made for voltage of 33kV, 69kV, 132kV, 230KV, 300kV, 400kV, 500kV ...

Mostly, the plymer post insulators are used to support bus-bars in transformer sub-station yards, support breakers in switchgear, and support capacitor banks etc. These plymer post insulators are generally subjected to bending, torsion and compression forces in service. They may also be installed horizontally, vertically, or underhung some times, and different installations will be accoring to different applications. They can be designs according to IEC, ANSI and other standards or to customer specification, in the factory of GW.

When do we need to replace the porcelain post insulators by composite plymeric station post insulators?

The mechanical heights are the same and electrical performance is comparable to the porcelain ANSI TR Numbers. This means in most cases they are direct replacements, one to one.

For many years substations were constructed using porcelain post insulators. After working so many years, many porcelain post insulators need to be replaced. But the height of many porcelain post insulators used before are different from what we are using today. That make it hard to use new ones to replace the old ones directly.

However, Xiangyang Guowang's composite station post insulators offer a better choice, that is to say we can offer composite station post insulators with appropriate height that can directly replace the old porcelain ones without adjust the bus or switches.

Besides, the composite station post insulators are usually cheaper than the porcelain station insulator.

Also composite station post insulators can be made to one piece, instead of installed together by several shorter ones.

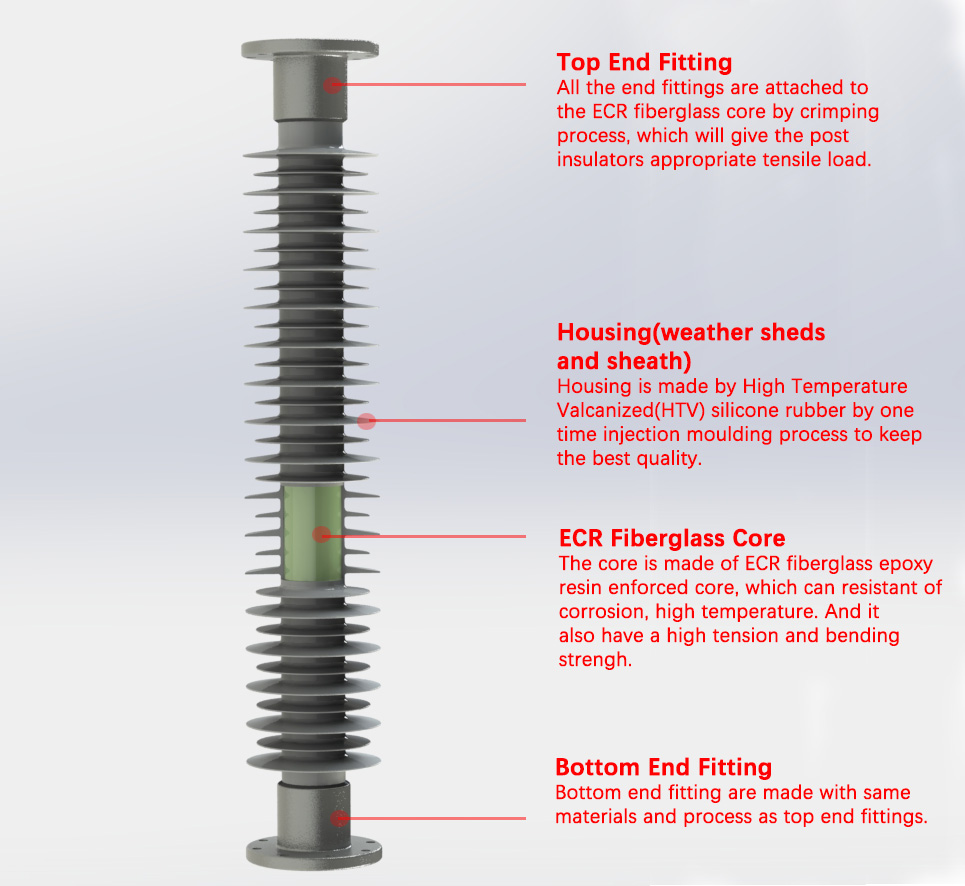

Structure and process of the composite post insulators

Housing (sheath and sheds)

Sheath and sheds of composite long rod polymer Insulators are made of HTV silicone-rubber (VMQ - Vinyl-Methyl-Polysiloxane, with filler additives) free of EPDM or other natural origin rubbers.Silicone-rubber is HTV solid silicone type (High Temperature Vulcanized – solid silicone rubber).This type of silicone rubber is solid and vulcanizes at a high temperature (near 200ºC).

Core

The ECR fiberglass rod, which produced from epoxy resin and glass fiber, has ability of high electrical integrity & high resistance to acid corrosion. Epoxy resin resistant to hydrolisys reinforced with glass fiber resistant to corrosion in order to transmit the mechanical stresses produced by conductors to the support and provides the necessary electrical insulation.The core is the component to bear mechanical load and has minimum tension strength at 1000Mpa.

Molding Process

compare with compression molding way, injection type insulators molding will make the thickness of insulator's housing more balance, which can get a much higher quality products. Also the injection machine is equipted with cold runner system, which will make the rubber the keep in melting status, during flowing inside the mold.

Functions

Composite Station post insulators have the advantages of anti-pollution flashover, high strength, light weight, anti-impact, easy for maintenance and project costs saving etc. The composite post insulators are widely applied to:

- Post-type circuit breaker

- Disconnector

- Electric reactor

- Converter valve

Advantages

- Excellent performance of hydrophobicity, anti-aging, anti-tracking, anti-erosion.

- High tension & bending strength, high mechanical strength, anti-impact, shake-proof and not fail easily for brittle.

- Light weight & small, convenient for installation, the dimensions can be customized, and interchangeable with porcelain post insulators.

- Don’t need to be manually cleaned, which make it safer.

- Application: post-type circuit-breaker, disconnector, current limiting reactor, paralleling resistor, converter valve and many other outer insulation posts of equipment.

Reference Project

|

|

|

| Composite post insulators are applied to Hunan-Hubei soft current exchanging tower of direct current power transmission system. It works normally and don’t need to be clean which save a lot labor cost. |

In the current exchange station of ±800KV ultra high voltage direct current power transmission substation. One piece pole post insulators are used to replace porcelain post insulators which need more than 3 pieces mounted together. | Composite post insulators can be applied for disconnectors, switchgears in substation with voltage of 11kV – 500kV. The post can be made in one piece. Or it can be installed together with several pieces |

Parameters (IEC 60273)

| Technical Refemrence Number | Model | BIL Rating kV | Power Frequency Withstand Wet | Height mm | Leakage Distance mm | Bolt Circle mm | Cantilever Strength kN | Torsional Strength N·M | |

| top | base | ||||||||

| C2-325 | GW-325-CT6 | 325 | 140 | 770 | 2150 | 127 | 127 | 6 | 2000 |

| C4-325 | |||||||||

| C6-325 | GW-325-CT8 | 1950 | 127 | 127 | 8 | 3000 | |||

| C8-325 | |||||||||

| C10-325 | GW-325-CT12.5 | 1800 | 127 | 127 | 12.5 | 4000 | |||

| C12.5-325 | |||||||||

| C16-325 | GW-325-CT16 | 2000 | 127 | 225 | 16 | 5000 | |||

| C20-325 | GW-325-CT20 | 2000 | 127 | 254 | 20 | 6000 | |||

| C2-450 | GW-450-CT5 | 450 | 185 | 1020 | 3000 | 127 | 127 | 5 | 1800 |

| C4-450 | GW-450-CT8 | 2800 | 127 | 127/178 | 8 | 2500 | |||

| C6-450 | GW-450-CT10-1 | 2700 | 127 | 127/178 | 10 | 3500 | |||

| C8-450 | GW-450-CT10-2 | 2700 | 127 | 127/200 | 10 | 4000 | |||

| C10-450 | GW-450-CT10-3 | 2700 | 127 | 127/225 | 10 | 4000 | |||

| C12.5-450 | GW-450-CT12.5 | 2950 | 127 | 225 | 12.5 | 6000 | |||

| C16-450 | GW-450-CT16 | 2950 | 127 | 254 | 16 | 6000 | |||

| C20-450 | GW-450-CT20 | 2950 | 127 | 254 | 20 | 6000 | |||

| C2-550 | GW-550-CT6-1 | 550 | 230 | 1220 | 3600 | 127 | 127 | 6 | 2000 |

| C4-550 | GW-550-CT6-2 | 3600 | 127 | 127/178 | 6 | 3000 | |||

| C6-550 | GW-550-CT8-1 | 3350 | 127 | 127/200 | 8 | 4000 | |||

| C8-550 | GW-550-CT8-2 | 3350 | 127 | 127/200 | 8 | 4000 | |||

| C10-550 | GW-550-CT10 | 3350 | 127 | 127/225 | 10 | 4000 | |||

| C12.5-550 | GW-550-CT12.5 | 3750 | 127 | 254 | 12.5 | 6000 | |||

| C16-550 | GW-550-CT16 | 3750 | 127 | 254 | 16 | 6000 | |||

| C20-550 | GW-550-CT20 | 3750 | 127 | 275 | 20 | 6000 | |||

| C2-650 | GW-650-CT6-1 | 650 | 275 | 1500 | 4600 | 127 | 127/178 | 6 | 2000 |

| C4-650 | GW-650-CT6-2 | 4600 | 127 | 127/200 | 6 | 3000 | |||

| C6-650 | GW-650-CT6-3 | 4600 | 127 | 127/200 | 6 | 3000 | |||

| C8-650 | GW-650-CT8 | 4800 | 127/225 | 127/225 | 8 | 4000 | |||

| C10-650 | GW-650-CT10 | 4800 | 127/225 | 254 | 10 | 4000 | |||

| C12.5-650 | GW-650-CT12.5 | 4800 | 127/225 | 254 | 12.5 | 6000 | |||

| C16-650 | GW-650-CT16 | 4650 | 225 | 275 | 16 | 6000 | |||

| C20-650 | GW-650-CT20 | 4700 | 225 | 300 | 20 | 6000 | |||

| C2-750 | GW-750-CT4-1 | 750 | 325 | 1700 | 5100 | 127 | 127/178 | 4 | 2000 |

| C4-750 | GW-750-CT4-2 | 5100 | 127 | 127/200 | 4 | 3000 | |||

| C6-750 | GW-750-CT6 | 4800 | 127/225 | 127/225 | 6 | 3000 | |||

| C8-750 | GW-750-CT8 | 5300 | 127/225 | 127/225 | 8 | 4000 | |||

| C10-750 | GW-750-CT10 | 5300 | 127/225 | 254 | 10 | 4000 | |||

| C12.5-750 | GW-750-CT12.5 | 5200 | 127/225 | 254 | 12.5 | 6000 | |||

| C16-750 | GW-750-CT16 | 5200 | 225/254 | 275 | 16 | 6000 | |||

| C20-750 | GW-750-CT20 | 5200 | 225/254 | 300 | 20 | 6000 | |||

| C4-850 | GW-850-CT4 | 850 | 360 | 1900 | 5800 | 127 | 200 | 4 | 3000 |

| C6-850 | GW-850-CT6 | 5500 | 127/225 | 225 | 6 | 3000 | |||

| C8-850 | GW-850-CT8 | 6000 | 127/225 | 254 | 8 | 4000 | |||

| C10-850 | GW-850-CT10 | 6000 | 127/225 | 254 | 10 | 4000 | |||

| C12.5-850 | GW-850-CT12.5 | 6000 | 127/225/254 | 254 | 12.5 | 6000 | |||

| C16-850 | GW-850-CT16 | 6000 | 225/254 | 275 | 16 | 6000 | |||

| C20-850 | GW-850-CT20 | 6000 | 225/254 | 300 | 20 | 6000 | |||

| C4-950 | GW-950-CT4 | 950 | 395 | 2100 | 6200 | 127 | 200 | 4 | 3000 |

| C6-950 | GW-950-CT6 | 6900 | 127/225 | 225 | 6 | 3000 | |||

| C8-950 | GW-950-CT8 | 6900 | 127/225 | 254 | 8 | 4000 | |||

| C10-950 | GW-950-CT10 | 6900 | 127/225 | 254 | 10 | 4000 | |||

| C12.5-950 | GW-950-CT12.5 | 6900 | 127/225/254 | 275 | 12.5 | 6000 | |||

| C16-950 | GW-950-CT16 | 6700 | 225/254 | 300 | 16 | 6000 | |||

| C20-950 | GW-950-CT20 | 6700 | 225/254 | 325 | 20 | 6000 | |||

| C4-1050 | GW-1050-CT4 | 1050 | 460 | 2300 | 6900 | 127 | 200 | 4 | 3000 |

| C6-1050 | GW-1050-CT6 | 7700 | 127/225 | 225 | 6 | 3000 | |||

| C8-1050 | GW-1050-CT8 | 7700 | 127/225 | 254 | 8 | 4000 | |||

| C10-1050 | GW-1050-CT10 | 7700 | 127/225 | 275 | 10 | 4000 | |||

| C12.5-1050 | GW-1050-CT12.5 | 7700 | 127/225/254 | 275 | 12.5 | 6000 | |||

| C16-1050 | GW-1050-CT16 | 7600 | 225/254 | 300 | 16 | 6000 | |||

| C20-1050 | GW-1050-CT20 | 7600 | 225/254 | 325 | 20 | 6000 | |||

| C4-1175 | GW-1175-CT4 | 1175 | 2650 | 8050 | 127/225 | 225 | 4 | 3000 | |

| C6-1175 | GW-1175-CT6 | 9000 | 127/225 | 254 | 6 | 3000 | |||

| C8-1175 | GW-1175-CT8 | 9000 | 127/225 | 254 | 8 | 4000 | |||

| C10-1175 | GW-1175-CT10 | 9000 | 127/225 | 275 | 10 | 4000 | |||

| C12.5-1175 | GW-1175-CT12.5 | 8900 | 127/225/254 | 300 | 12.5 | 6000 | |||

| C16-1175 | GW-1175-CT16 | 8900 | 225/254 | 325 | 16 | 6000 | |||

| C20-1175 | GW-1175-CT20 | 8900 | 225/254 | 356 | 20 | 6000 | |||

| C4-1300 | GW-1300-CT4 | 1300 | 2900 | 10000 | 127/225 | 225 | 4 | 3000 | |

| C6-1300 | GW-1300-CT6 | 10000 | 127/225 | 254 | 6 | 3000 | |||

| C8-1300 | GW-1300-CT8 | 10000 | 127/225 | 275 | 8 | 4000 | |||

| C10-1300 | GW-1300-CT10 | 10000 | 127/254 | 275 | 10 | 4000 | |||

| C12.5-1300 | GW-1300-CT12.5 | 9850 | 127/225/254 | 300 | 12.5 | 6000 | |||

| C16-1300 | GW-1300-CT16 | 9750 | 225/254 | 325 | 16 | 6000 | |||

| C20-1300 | GW-1300-CT20 | 9750 | 225/254 | 356 | 20 | 6000 | |||

| C4-1425 | GW-1425-CT4 | 1425 | 3150 | 11000 | 127/225 | 225 | 4 | 3000 | |

| C6-1425 | GW-1425-CT6 | 11000 | 127/225 | 254 | 6 | 3000 | |||

| C8-1425 | GW-1425-CT8 | 11000 | 127/225 | 275 | 8 | 4000 | |||

| C10-1425 | GW-1425-CT10 | 11000 | 127/225 | 300 | 10 | 4000 | |||

| C12.5-1425 | GW-1425-CT12.5 | 10850 | 127/225/254 | 325 | 12.5 | 6000 | |||

| C16-1425 | GW-1425-CT16 | 10750 | 225/254 | 356 | 16 | 6000 | |||

| C20-1425 | GW-1425-CT20 | 10600 | 225/254 | 356 | 20 | 6000 | |||

| C4-1550 | GW-1550-CT4 | 1550 | 3350 | 11700 | 127/225 | 225 | 4 | 3000 | |

| C6-1550 | GW-1550-CT6 | 11700 | 127/225 | 254 | 6 | 3000 | |||

| C8-1550 | GW-1550-CT8 | 11700 | 127/225 | 275 | 8 | 4000 | |||

| C10-1550 | GW-1550-CT10 | 11600 | 127/225 | 300 | 10 | 4000 | |||

| C12.5-1550 | GW-1550-CT12.5 | 11600 | 127/225/254 | 325 | 12.5 | 6000 | |||

| C16-1550 | GW-1550-CT16 | 11600 | 225/254 | 356 | 16 | 6000 | |||

| C20-1550 | GW-1550-CT20 | 11400 | 225/254 | 356 | 20 | 6000 | |||

| C4-1675 | GW-1675-CT4 | 1675 | 3650 | 13000 | 127/225 | 254 | 4 | 3000 | |

| C6-1675 | GW-1675-CT6 | 13000 | 127/225 | 275 | 6 | 3000 | |||

| C8-1675 | GW-1675-CT8 | 13000 | 127/225 | 300 | 8 | 4000 | |||

| C10-1675 | GW-1675-CT10 | 12800 | 127/225 | 300 | 10 | 4000 | |||

| C12.5-1675 | GW-1675-CT12.5 | 12800 | 225/254 | 325 | 12.5 | 6000 | |||

| C16-1675 | GW-1675-CT16 | 12650 | 225/254 | 356 | 16 | 6000 | |||

| C4-1800 | GW-1800-CT4 | 1800 | 4000 | 14200 | 225/254 | 254 | 4 | 3000 | |

| C6-1800 | GW-1800-CT6 | 14200 | 225/254 | 275 | 6 | 3000 | |||

| C8-1800 | GW-1800-CT8 | 14200 | 225/254 | 300 | 8 | 4000 | |||

| C10-1800 | GW-1800-CT10 | 14200 | 225/254 | 325 | 10 | 4000 | |||

| C12.5-1800 | GW-1800-CT12.5 | 14000 | 225/254 | 356 | 12.5 | 6000 | |||

| C16-1800 | GW-1800-CT16 | 13850 | 225/254 | 356 | 16 | 6000 | |||

| C4-1950 | GW-1950-CT4 | 1950 | 4400 | 15650 | 225/254 | 254 | 4 | 3000 | |

| C6-1950 | GW-1950-CT6 | 15650 | 225/254 | 275 | 6 | 3000 | |||

| C8-1950 | GW-1950-CT8 | 15450 | 225/254 | 300 | 8 | 4000 | |||

| C10-1950 | GW-1950-CT10 | 15350 | 225/254 | 325 | 10 | 4000 | |||

| C12.5-1950 | GW-1950-CT12.5 | 15350 | 225/254 | 356 | 12.5 | 6000 | |||

| C4-2100 | GW-2100-CT4 | 2100 | 4700 | 16400 | 225/254 | 254 | 4 | 3000 | |

| C6-2100 | GW-2100-CT6 | 16400 | 225/254 | 275 | 6 | 3000 | |||

| C8-2100 | GW-2100-CT8 | 16400 | 225/254 | 300 | 8 | 4000 | |||

| C10-2100 | GW-2100-CT10 | 16400 | 225/254 | 325 | 10 | 4000 | |||

| C12.5-2100 | GW-2100-CT12.5 | 16400 | 225/254 | 356 | 12.5 | 6000 | |||

| C4-2250 | GW-2250-CT4 | 2250 | 5000 | 17800 | 225/254 | 254 | 4 | 3000 | |

| C6-2250 | GW-2250-CT6 | 17800 | 225/254 | 300 | 6 | 3000 | |||

| C8-2250 | GW-2250-CT8 | 17800 | 225/254 | 325 | 8 | 4000 | |||

| C10-2250 | GW-2250-CT10 | 17800 | 225/254 | 356 | 10 | 4000 | |||

| C12.5-2250 | GW-2250-CT12.5 | 17800 | 225/254 | 356 | 12.5 | 6000 | |||

| C4-2400 | GW-2400-CT4 | 2400 | 5300 | 19100 | 225/254 | 254 | 4 | 3000 | |

| C6-2400 | GW-2400-CT6 | 19100 | 225/254 | 300 | 6 | 3000 | |||

| C8-2400 | GW-2400-CT8 | 19100 | 225/254 | 325 | 8 | 4000 | |||

| C10-2400 | GW-2400-CT10 | 18900 | 225/254 | 356 | 10 | 4000 | |||

| C12.5-2400 | GW-2400-CT12.5 | 18900 | 225/254 | 356 | 12.5 | 6000 | |||

| C4-2550 | GW-2550-CT4 | 2550 | 5700 | 20500 | 225/254 | 275 | 4 | 3000 | |

| C6-2550 | GW-2550-CT6 | 20500 | 225/254 | 300 | 6 | 3000 | |||

| C8-2550 | GW-2550-CT8 | 20500 | 225/254 | 325 | 8 | 4000 | |||

| C10-2550 | GW-2550-CT10 | 20500 | 225/254 | 356 | 10 | 4000 | |||

FAQ

What is BIL for post insulator?

Insulation levels are designed to , rather than only normal operating voltages. Since the insulation lines and equipment is protected by surge arresters draining the surges rapidly before the insulation is damaged, the arrester must operate below the minimum insulation level that must withstand the surges.